While working with precision sources, we have to consider its accuracy over its full usable temperature range. We will discuss potential ways of minimizing temperature drift due to trimmer potentiometer (POT).

The accuracy of the current output depends on the values of the resistor ratio formed by the resistors. But using a trimmer potentiometer, we can overcome the total errors in the resistor values. But by adding a potentiometer, we end up paying a heavy price as they have a large temperature coefficient. So, as the ambient temperature changes with time, the resistor value also changes, and so does our current output.

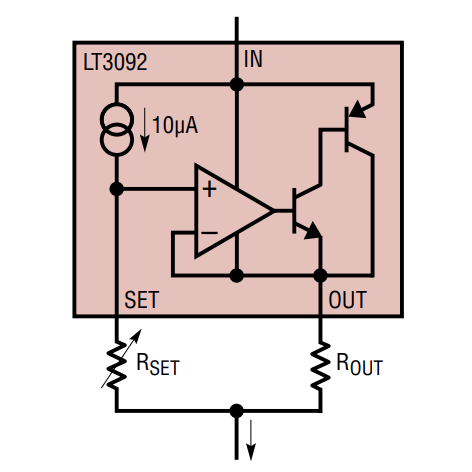

LT3092 datasheet shows a neat trick. It suggests choosing resistors from the same series. Due to this, they will have the same amount of temperature drift. Hence, ratiometrically our current output remains the same.

But adding a potentiometer at the input introduces a drift imbalance between input and output. That is to say, drift due to the potentiometer will remain uncompensated.

Some calculations

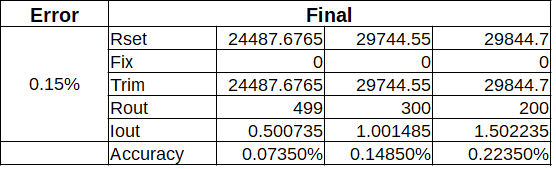

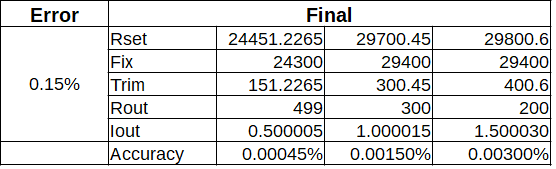

For example, let’s consider a reasonably priced potentiometer that might have 100ppm/°C of drift. Now let’s say we are using the device in the temperature range of 25°C to 40°C. Thus, the final temperature drift of the potentiometer will become 100ppm times 15°C which equals 1500ppm. That is 0.15% of the full-scale readings.

The following table shows the output current error caused due to the temperature drift of a single 30kΩ potentiometer when used as shown in the example circuit of the LT3092 datasheet.

The error in the highest range is 0.22%, which is unacceptable!

To improve that, we can use a high-value resistor in series with a low-value potentiometer minimizing temperature drift caused by the trimmer potentiometer.

There are various other methods to compensate for this drift. Refer to this brilliant application-note by ON Semiconductor for further information. “AND8415 Minimizing the Temperature Dependence of Digital Potentiometers (POTs)“

Other posts from the Precision Current Source series:

- Precision Current Source: Part One where we discussed the need for a precision current source and defined its features

- Precision Current Source: Part Two where we discussed how to improve systems temperature drift by minimizing potentiometer temperature drift

49206d69737320796f75204461646121

Pingback: Precision Current Source : Part Three - Yash Kudale's | Personal Blog