With their popularity among hobbyists and professionals alike, PCB Power is one of the top choices for PCB manufacturing in India. With their industry-leading online quotation system and hassle-free service, they have earned their place in the market. In addition to it they also works with a small quantity manufacturing run. Where as with traditional manufacturers you might struggle to get a simple quote.

I recently had a chance to work with PCB Power on a flex PCB design and here is my review of their offering.

First things first, this was a design I made for a friend. I am not allowed to say what it does but let me give you what were the manufacturing requirements of the design.

I have reviewed their rigid PCB previously in “PCB Power’s PCB manufacturing review”, I will refer to a few pros and cons I observed in my last review to see what has changed.

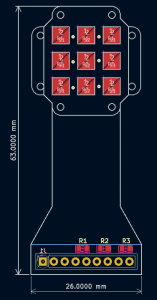

Given PCB Specifications:

- Dimensions: 63 mm x 26 mm

- Layers: 2

- Copper Thickness: 35 µm

- Material: Polyimide

- FPC Thickness: 0.18 mm

- Surface Finish: Immersion Gold / ENIG

- Stiffener Top: Yes, FR4, 1 mm thick

- Stiffener Bottom: Yes, FR4, 1 mm thick

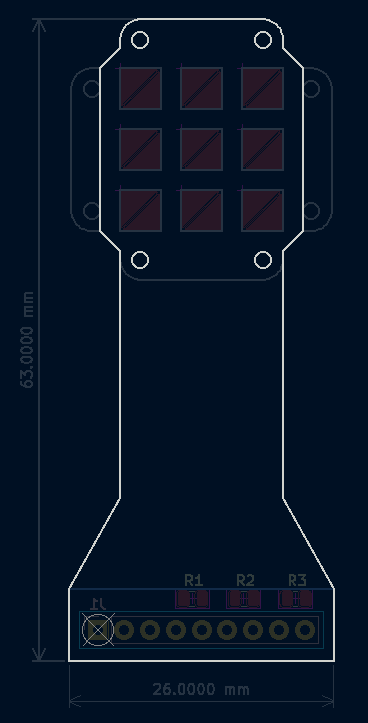

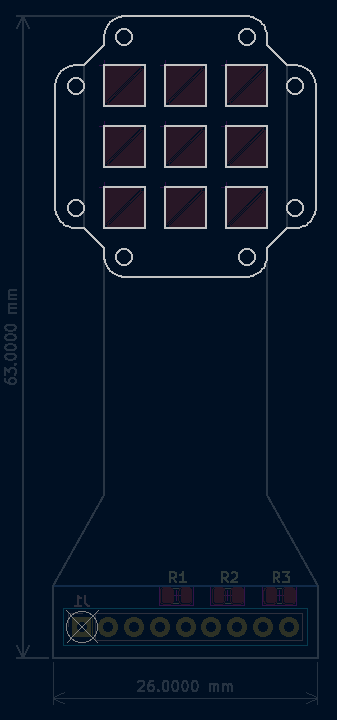

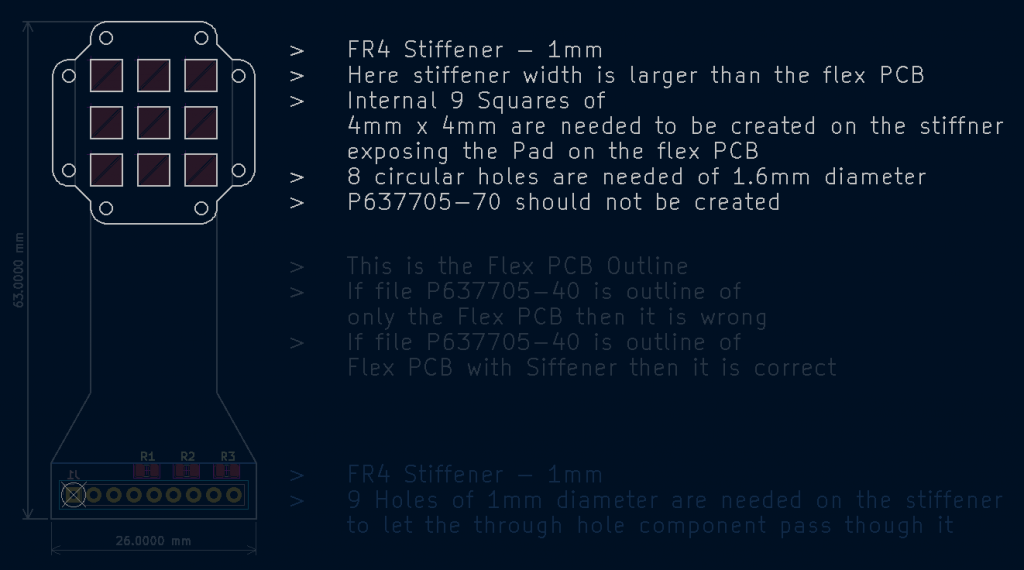

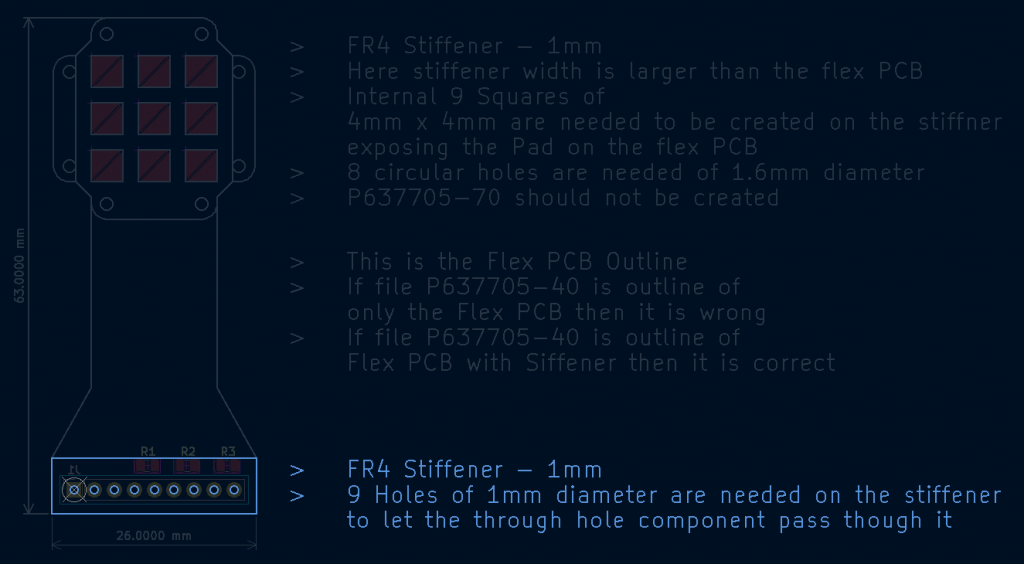

My Flex PCB Design:

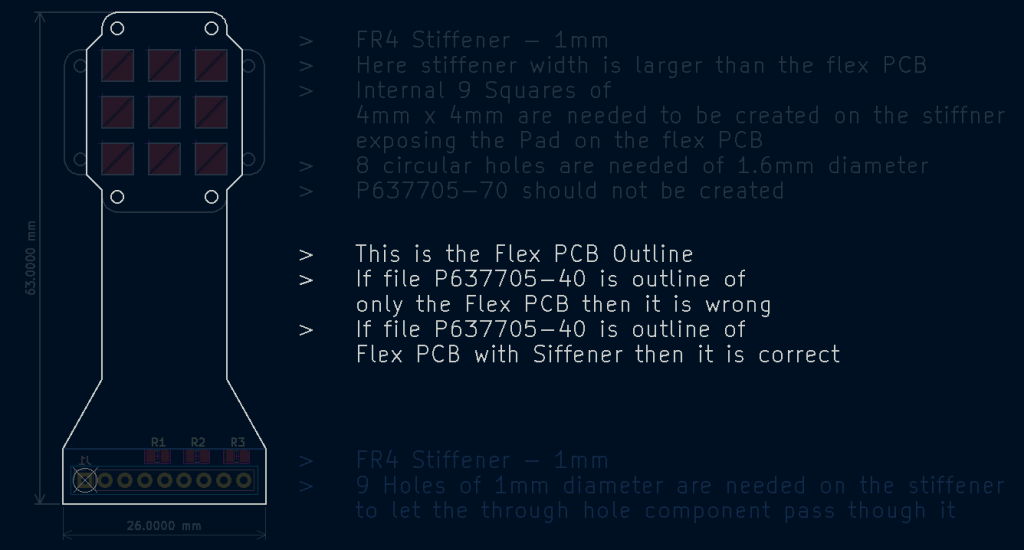

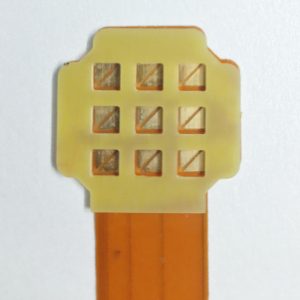

As you may have noticed a couple of interesting requirements for the design. It has stiffeners added on the top and bottom side of the PCB. Here is the image of the design.

For people who don’t know, one usually specifies two new layers for the top and bottom stiffeners, as there is no way of representing the shape and location of stiffeners in PCB CAD tools. This with a good amount of design notes, on respective layers can make the manufacturer’s life easy and lowers the number of exceptions raised.

PCB Power quoted me a reasonable cost for manufacturing this flex design which was obviously higher than usual rigid PCBs. I used their online portal to place the order.

As this was a new format for me I was expecting some exceptions (here exception means queries raised by the manufacturer). Luckily the only exception I got was on the increased thickness of the PCB due to the selected copper thickness. It changed from 0.18 mm to 0.22 mm, which was fine for the targeted flexibility of the design. There were a couple of other suggestions but they didn’t alter the design much. But looking at their generated files I noticed they misinterpreted a few things and thus I added additional comments in the Gerbers and got on call with them.

We discussed on the exceptions and resolved them. I also added additional notes in the Gerbers. So, I was expecting near-perfect PCBs at this point.

Now let’s get into PCB Power’s Flex PCB review. Spoiler alert I got a 50% yield on my 10 PCB run.

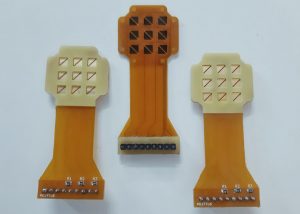

What I got:

The Good:

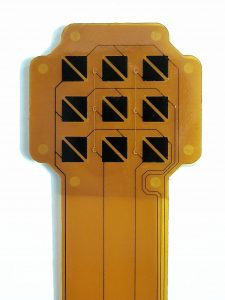

The quality of the actual flex seemed good. The traces and pads look good. The stiffener shape and internal squares with-in the top stiffener is as per the design.

And that’s all the good I have to say about it.

The Bad:

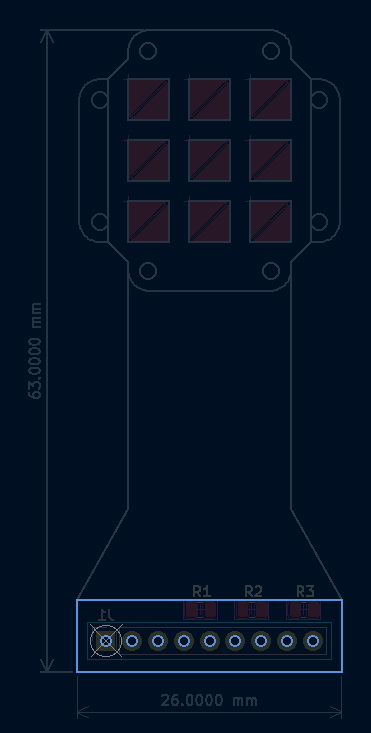

Missing Holes & Poor Drill Alignment:

First of all, there were some obvious issues with Flex. One of the major ones was that they didn’t drill holes in the flex or on the top stiffener. I used slots in the edge cut layer to shows the holes needed. I had discussed the same during my call with PCB Power. But still they didn’t drill the holes. Also in the image you can notice holes in the inner layer but the overlay might have covered them. I had to drilled the holes later manually but as a couple of holes were close to traces it was risky to do so.

If you notice carefully on the vias between the rows of pads, the via holes do not aligned with their pads. This was never my experience with rigid PCBs from PCB Power.

Badly Aligned Stiffener:

As there were two stiffeners one on top and one on the bottom, many of the PCBs had either one or both unaligned with the flex. This made them unusable as unaligned stiffener covered the pads under them. This happened with 4/10 Flex PCBs.

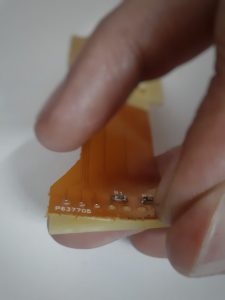

Undone Stiffener:

A couple of PCBs had their stiffener already separating from the underlying flex.

Delay In Delivery:

If you check my earlier review of PCB Power’s PCB manufacturing review I mentioned that they delivered the PCBs within a week. This unfortunately has changed for the worse. And no, this is not due to this being a flex design, it is something that I have observed over the years. They are unable to deliver standard stack-ups like 4-layer rigid PCBs in time. The delay is still there even after paying for faster delivery. This is not just my opinion it is the opinion of many industry veterans. One also mentioned that they have stop paying for the early shipment, as there is no point in doing so.

Conclusion:

This time around, quality of PCB from PCB Power was underwhelming. Delay in delivery is a growing and is an known issue with them. After getting 50% yield from this run, it clearly shows that flex manufacturing might be new to them and they are still refining their process. The good thing is there is more competition in the PCB manufacturing space now. And I hope to review their offerings soon.