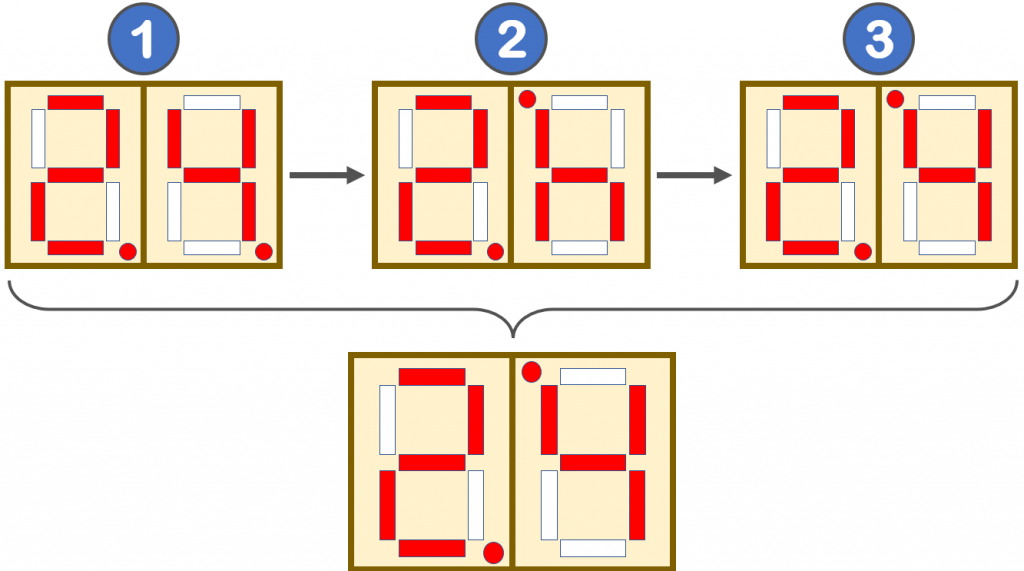

While running yesterday, I noticed how this treadmill manufacturer used standard 7-segment displays with a decimal point to create a colon. The image shows the manufacturer rotating the 7-segment display and using its decimal point to form a colon for a clock. But why go through this effort? To understand that, let’s discuss reducing BOM items and designing for manufacturing.

Going into production, especially assembly, one of the subtle cost-driving factors is the number of items in BOM. As the number of components increases in a given design, the effort in sourcing, testing, and maintaining them increases too. Furthermore, during assembly, an extra rail is needed to be added in case of automated pick and place machine is used. All these factors individually contribute to incremental cost increases but, as a whole, can be a significant portion of the product cost.

Hence to minimize cost, Engineers perform DFM – Design for Manufacturing reviews. DFM encompasses many checks. Specifically today we are discussing Reducing BOM cost or BOM optimization.

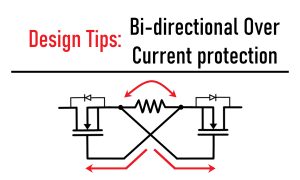

To give you a typical example, let’s consider a circuit using a 2K ohm resistor. But if a 1K ohm resistor is already present elsewhere in the design. So for BOM optimization, we can use two 1K resistors in series instead of adding another part, thus reducing BOM items.

But there are no free lunches in the world. So the designer had to keep the pinout the same and create a custom character matrix to show the numbers inverted. Or he wired the segments such that a generic number matrix can display numbers on the rotated 7-segment. Refer image above for a better understanding.

To deep dive further into DFM, you can check out this detailed article on DFM analysis.

Click here to find other interesting design tips.