First of all Happy New Year fellow engineers !

This post is about reviewing PCB manufacturers in Pune. I had to start from scratch on this one, didn’t find any helpful post about this on the internet. So here is my note on the matter, hope it will be helpful. This post is based on the trial run of a small quantity of PCB for my personal projects but few of the manufacturers I used also do PCBs in quantity, contact links at the end of the post.

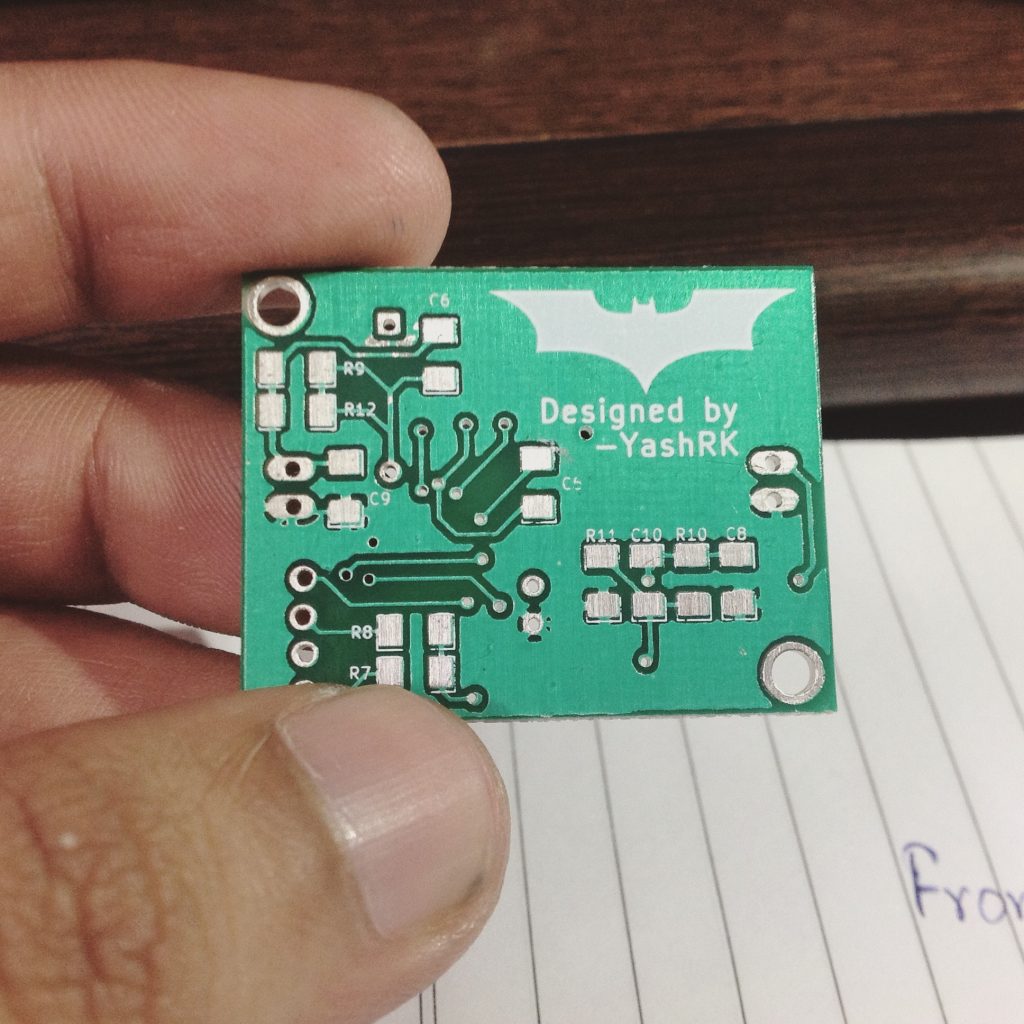

Slaping on the Batman logo where ever you can. Its just nerd written all over it !!

Introduction

So here is how it went, I had two design laying around I needed to be manufactured one was a through-hole design and another one was SMD design.

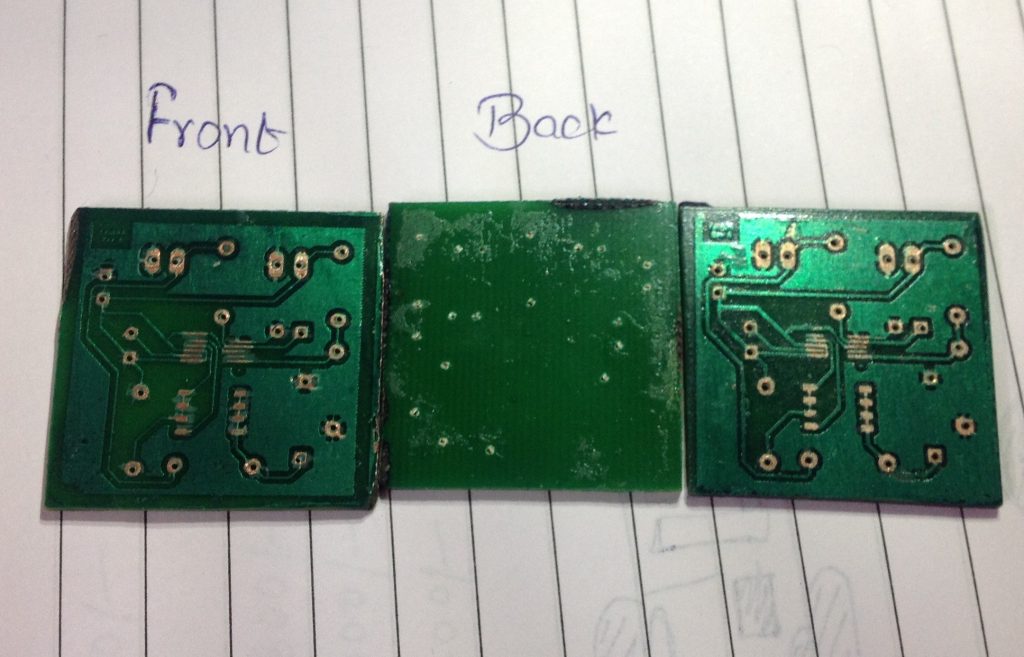

Through-hole PCB was based on led driver IC which was in SMD and that driver needed a P-channel MOSFET as an external transistor which I happened to have in an SMD package so all in all the board wasn’t totally through-hole but to keep the PCB cost low I flipped the SMD components to the bottom layer and made it a single-sided board.

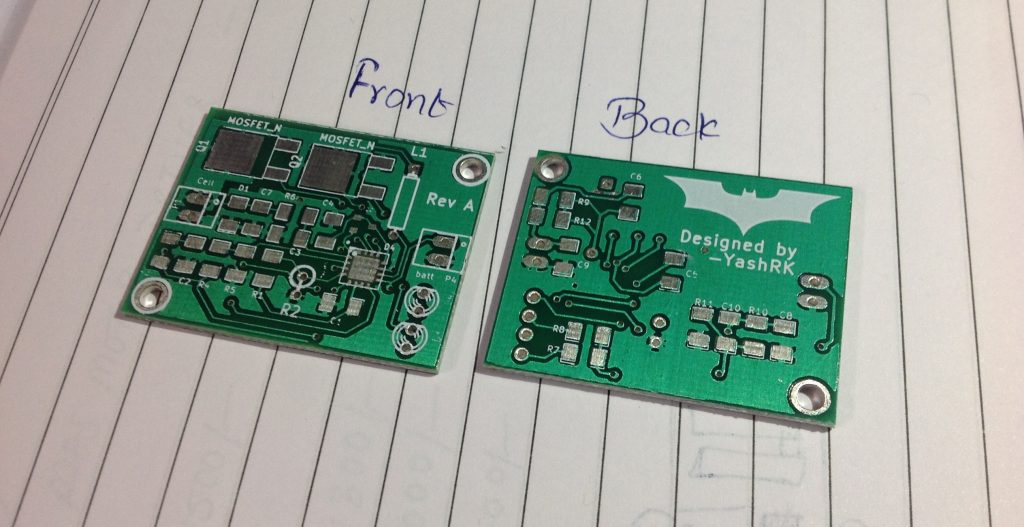

The SMD one is a charger IC is totally in SMD accept the thermistor and the inductor (I will be winding that my self).

Both of the PCB was less than 5cm x 5cm. So the cost was according to this specification.

So I called and passed my Gerbers all over the city, from the contacts I called only a few where working and from those, there were few who will do a quantity of 10, the costing I got from the PCB manufacturers (for the double-sided all SMD PCB for the quantity of 10) are,

(All costing are in Indian Rupees and including the tooling cost)

Aakash Electronics – 1500/-,

Trident – 6000/- (and I am quite sure they were not kidding),

Diya Electronics – 2 Rs/ cm² that’s around 50/- which is reasonable but they had very high tooling cost which amounts to the total of 4000/-

A J Enterprise, Wakad- 2700/-

For the single-sided PCB boards I had already chosen Tech Leaf, their service was cheap and they were the closest to my location.

Tech Leaf – 50 Rs (min) or 1Rs/cm² (whichever is the maximum) delivered.

In the end, I trickled down to 3 manufacturers considering their quote and feasibility of location, Tech Leaf for single-sided PCB, AJ Enterprise and Aakash Electronics for the double-sided load.

The PCB didn’t come with any silkscreen that was told to me beforehand. I wasn’t expecting anything “good” at this price and there wasn’t anything good to say anyway. Etching turned out to be good enough but the solder mask layer ruined the whole PCB. As seen in the picture the solder mask covered the pads due to its fine pitch of the SMD package. The drilling work was average but was workable enough.

In the end the PCB where usable if you scrape off the solder mask and I am going to use their service for basic prototyping and mostly with trough hole design and this what they advertise for anyway. At this price, it’s just doesn’t seem practical to bother and make PCB at home.

There is nothing much to say about this one, it cost me around 3000/- to make a batch of 10 that is 6 times what it cost me to make previous PCB form Tech Leaf and certainly you get what you pay for!

Everything is almost perfect with this PCB, the only fault I found was that the silkscreen was faded at a few locations but everything else was perfect. The plating on the walls for the via and the through-hole components was good and each process done on the PCB was adequately accurate. Importantly the Batman Logo turned out to be perfect!

For the last one Aakash Electronics, I didn’t have any more board design to be manufactured so I have to wait but I do have few designs in the pipeline, so it won’t take long to review them. According to images I have seen online of their PCBs they are quite good and are comparable to the AJ ones. They quoted me 150/- for one PCB for a batch of ten that is half of what I got AJ PCB’S for.

Which service to use?

It depends, on what you want to make PCBs for? If it’s for your college project or just one-off broads use Tech Leaf. If you want in 10s or 100s in quantity then you should go for AJ Enterprise or Aakash Electronics. For anything more. I am sure you won’t be reading this if you are working at that quantity.

Hello sir,

For the pcb designing which type of software had you used

I use an open source cad software called KiCAD it’s awesome you should give it a try!

Good read – we have been working with a pcb manufacturer that specialises in sustainable pcb’s which recycle easier for precious metal recovery – so i need to read up more to better help the client.